4 reasons ESD grounding is critical for industrial workstations

In this post, we’ll give you an overview of why ESD grounding is essential and what you can do to protect your workspace.

Learn more about ESD grounding:

White paper: understanding esd grounding for industrial workstations

1. What is ESD grounding and why is it so important?

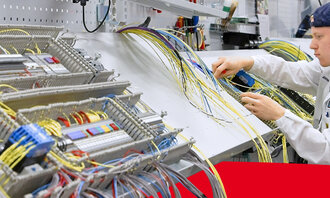

ESD grounding creates a direct path for static charges to dissipate safely into the earth, preventing them from damaging sensitive electronic equipment. Even a small static buildup—caused by something as simple as walking across a floor—can result in a discharge that destroys valuable components.

Proper grounding ensures that workstations, tools, and personnel are all at the same electrical potential, eliminating the risk of ESD damage.

2. How ESD protected areas (EPA) help control static?

An ESD Protected Area (EPA) is a controlled space where all materials, surfaces, and employees are kept at the same electrical potential. This keeps sensitive components safe from unexpected electrostatic discharge.

Setting up an EPA correctly requires detailed planning and consistent upkeep, as well as adherence to specific industry standards, such as ANSI/ESD S20.20 or IEC 61340-5-1, to protect sensitive components from static damage.

3. The key components of an ESD grounding system

While we won’t go into full detail here, every effective ESD system shares a few critical components:

- Grounding Points: Essential for directing static charges safely away.

- Conductive Surfaces: Ensure static charges are evenly distributed and grounded.

- ESD-Compatible Furniture: Helps integrate grounding points seamlessly into workstations.

Each of these components plays a vital role in creating a static-safe environment, but the specifics—such as what materials to use and how to arrange them—are detailed in our white paper: understanding esd grounding for industrial workstations

4. Overcoming the Challenges of ESD Grounding

Implementing an ESD grounding system isn’t without its challenges. Two of the most common issues are employee compliance and upgrading existing infrastructures. Employees often forget to follow ESD protocols, like wearing wrist straps, which can lead to costly mistakes.

Upgrading existing infrastructure also presents difficulties, as it can be expensive and disruptive. However, strategies such as gradual implementation, simplifying procedures, and regular employee training can help overcome these obstacles.

FAQ: Common Questions About ESD Grounding

What is the purpose of an ESD grounding system?

An ESD grounding system safely directs static electricity away from sensitive electronics, preventing damage that could occur due to electrostatic discharge.

How do you ensure employees comply with ESD protocols?

Compliance requires regular training, clear protocols, and easy-to-use grounding tools such as wrist straps and grounding points.

What are some key components of an ESD protection plan?

An effective ESD system requires grounding points, conductive surfaces, and ESD-safe furniture, all working together to create a static-safe environment.

Conclusion: Want to Protect Your Electronics from ESD?

Understanding the basics of ESD grounding is the first step in protecting your workspace, but the implementation requires careful planning and ongoing maintenance.

To increase your knowledge about ESD grounding, including best practices, key components, and solutions to common challenges, download our comprehensive white paper or watch the webinar about the subject.