What is a cobot and what are its advantages in industrial work?

In this article, we will go through what cobots are and what are the advantages of using them in an industrial work environment.

What is a cobot?

A cobot is a robot that cooperates with humans and does not need special safety devices around it. Unlike a regular robot, it can also be in contact with a human.

Cobots were originally born to improve the ergonomics of work and increase collaboration between humans and robots in various industries. Cobots are used to improve occupational health and safety, build more meaningful work environments for employees, and increase work efficiency and economic growth.

The structure of a cobot is often light, so that it can be safely integrated to work at the same workstation as a human. Cobots can also be mounted on mobile workstations, such as trolleys, so that they can be used in multiple workstations.

What kinds of tasks can a cobot perform?

Cobots can perform difficult, boring, repetitive work steps that easily cause musculoskeletal disorders. They can often also improve the safety of the work. Ergonomically challenging or monotonous work steps such as gluing, screwing, packing and tasks that require reaching are suitable to be transferred to a cobot.

Human-robot collaboration (HRC)

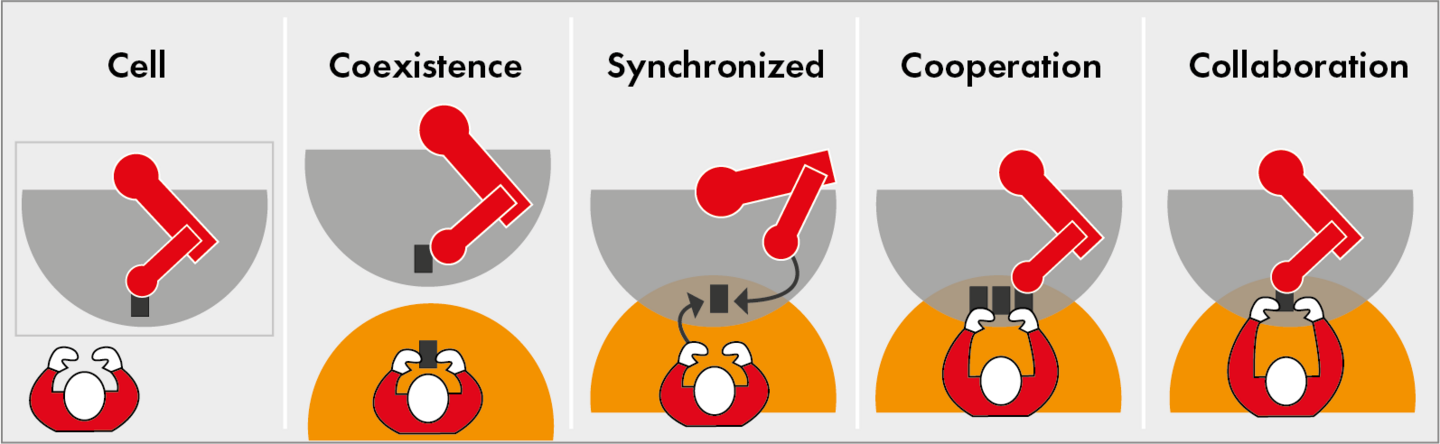

Cobots do not replace workers, but they collaborate with humans. In connection with cobots and robots, the term HRC is often used, which means human-robot collaboration. HRC has five different levels (levels of collaboration, LoC), which are determined according to the technical characteristics of the robot and the work requirements.

- Level 1: Cell

The human and the robot are working in different cells. - Level 2: Coexistence

The human and the robot are in the same environment, but they do not interact. - Level 3: Synchronized

The human and the robot work in the same space at different times. - Level 4: Cooperation

The human and the robot work in the same workspace at the same time, but they perform different tasks. - Level 5: Collaboration

The human and the robot perform a task together.

The Treston cobot trolley serves the customer's needs

Check out the video for an example of the Cobot trolley designed by Treston and ABB together.

The benefits of a Cobot workstation for the employer

Three out of five people of working age report work-related musculoskeletal disorders, and at the same time, working careers are getting longer. Sick leave and occupational health costs are constantly increasing. When a cobot workstation is planned at the workplace, the employer's interests often include minimising safety risks and production time, and improving quality and efficiency. These factors are also used as evaluation criteria for the success of cobot workstations.

- Less sick leave and decreased health care costs.

- Working careers get longer.

- Employees commit to their work.

- Employee performance can be optimised for work tasks that require skill.

- Employee motivation improves.

- Quality improves.

- Productivity increases.

- Production time is reduced.

The benefits of the cobot workstation for the employee

From the employee's point of view, healthier, safer, and less repetitive work improves motivation and the meaningfulness of work. Thanks to cobots, employees can also develop their own skills, and work time can be used for tasks that require more skill.

- Work is safer.

- Work is more meaningful because there are fewer monotonous tasks and repetitions.

- The risk of injury is reduced, which leads to healthier leisure time.

- There are fewer uncomfortable working postures.

- Satisfaction with one's work improves.

What kinds of challenges can occur with cobots?

Cobots have become significantly more common in recent years, and it can be proven that they have many good features in industrial work environments, but they also naturally come with challenges. It should be mentioned that working with technology can bring various psychological challenges to work.

Working with the cobot, as with other new tools, requires learning something new. The possibility to adjust the cobot's properties, such as speed, and proper familiarisation are important points to consider during commissioning.

Sources:

Guilherme Deola Borges, Paula Carneiro, and Pedro Arezes

Human Factors Effects on a Human-Robot Collaboration System: A Modelling Approach, University of Minho, Guimaraes, Portugal

- Federico Fraboni, Luca Gualtieri , Francesco Millo, Matteo De Marchi, Luca Pietrantoni, and Erwin Rauch

Human-Robot Collaboration During Assembly, Tasks: The Cognitive Effects of Collaborative, Assembly Workstation Features - Luca Gualtieri1, Federico Fraboni, Matteo De Marchi, and Erwin Rauch

Evaluation of Variables of Cognitive Ergonomics in Industrial Human-Robot Collaborative, Assembly Systems - Alberto Ranavolo, Giorgia Chini, Francesco Draicchio, Alessio Silvetti, Tiwana Varrecchia, Lorenzo Fiori, Antonella Tatarelli, Patricia Helen Rosen, Sascha Wischniewski, Philipp Albrecht, Lydia Vogt, Matteo Bianchi, Giuseppe Averta, Andrea Cherubini, Lars Fritzsche, Massimo Sartori, Bram Vanderborght, Renee Govaerts, and Arash Ajoudani

Human-Robot Collaboration (HRC) Technologies for Reducing Work-Related Musculoskeletal Diseases in Industry 4.0 - Guilherme Deola Borges, Paula Carneiro, and Pedro Arezes

Human Factors Effects on a Human-Robot Collaboration System: A Modelling Approach